What to avoid - and why...

Below are some of the pitfalls to avoid when purchasing a cattle crush or headbail.

All cattle crushes from National Stockyards are specifically designed to avoid these pitfalls.

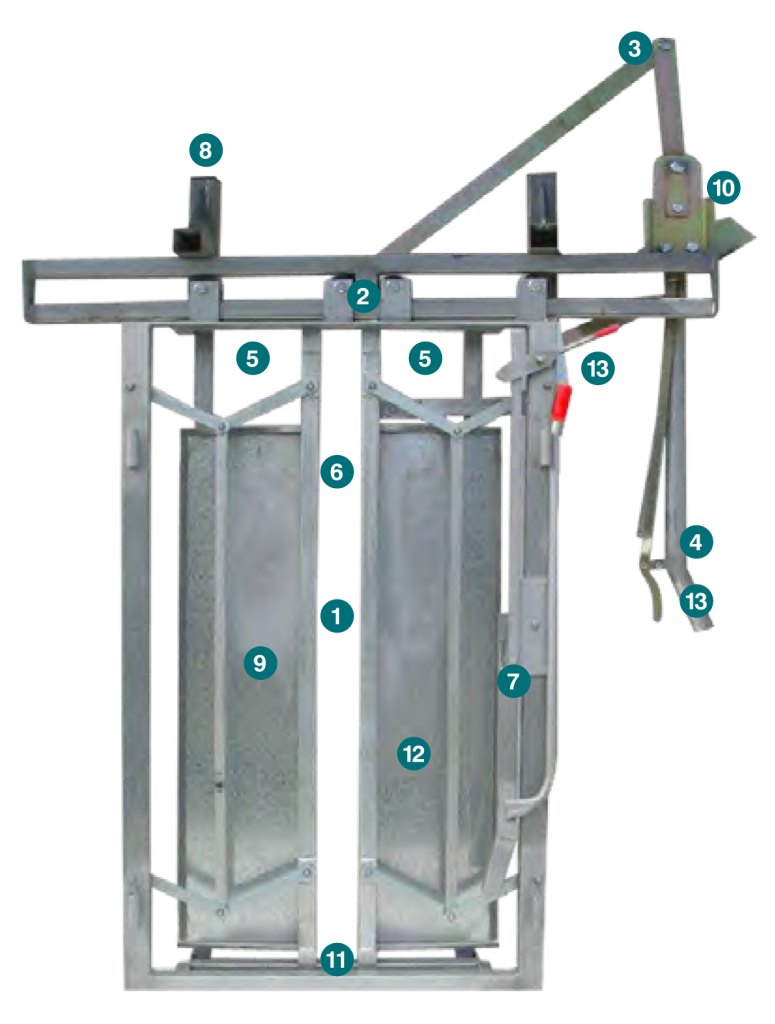

- A headbail that closes in increments of 30mm to 40mm. You cannot get that last click and the animal sucks back.

- Imported Headbails. Chinese Steel is inferior to Australian Made Steel. Tell tale signs are bolted together components, odd sized steel, stitch welding, touch up paint that does not match the rest of the paint, the reluctance of the supplier to offer options such as off side, and, shortcuts in the quality.

- Poorly designed linkage that does not give the operator mechanical advantage. Head husbandry is easier if the animal’s neck can be held securely.

- A crush or headbail that is heavy to use – gets tiresome after a few hundred head in a day.

- An animal can get a front leg over the top of the baffles and then sink down. It takes a lot of effort and strength to release the animal.

- Straight bail arms which allow excessive vertical head movement.

- Bruise or tear points as the animal exits the crush.

- Open holes allowing water to collect and rust.

- Thin sheet steel that rattles excessively and rusts out as water and dirt are collected in the seams.

- Bolt holes that are not sleeved. The RHS will wear quickly and elongate the hole

- A design allows for build up of dirt and rocks. Hard to close a headbail if there is a rock in the way.

- Excessive noise. Cattle hate noise.

- A headbail or chin lifter that cannot be released under pressure. It can only take a few seconds to choke an animal.

In addition to the Headbail, the following points apply to a poorly designed crush and is there any warranty offered?

- Crush bodies that are too short for an animal to stand in comfortably prior to catching – a big problem with many non vet access crushes on the market.

- Rail gaps in the crush body that will facilitate broken legs or operator injury. Even if a body gate is sheeted a large gap between the gate and the base frame has resulted in many animals breaking their shins.

- Rail gap spaces on the entry sliding gate that allow for an animal to get it’s head stuck.

- 2 way slam catches. If a beast kicks the gate you can be hurt.

- Imported Crushes. Chinese Steel is inferior to Australian Made Steel. Tell tale signs are bolted together crushes, odd sized steel, stitch welding, touch up paint that does not match the rest of the paint, the reluctance of the supplier to offer options such as off side operation or extra gates, and, shortcuts in the quality. You maybe told by an importer that their crushes bolt together to transport flat packed but they leave out the words (“in a container”)

- Excessive noise. Cattle hate noise.

- Many vet crushes on the market are too short for efficient Preg testing, Artificial Insemination, Scrotal measurements & Palpation & Udder inspections etc (some vet crushes sold are up to 500mm shorter in total length than our vet crushes)

- Is the crush too narrow for today’s modern cattle?

View more of our cattle crush range...

Menu

Menu

Menu

Menu