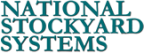

Loading Ramps Concrete Floor

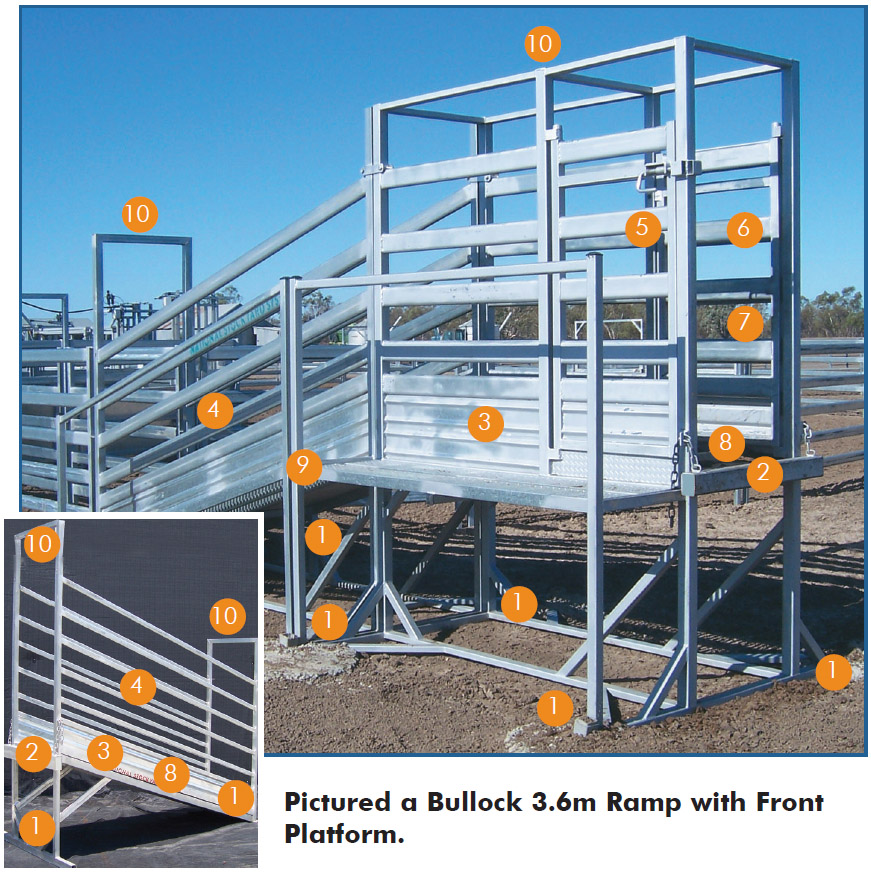

All National Stockyard Systems loading ramps are fully galvanised and feature a patented concrete floor (except budget) with plenty of treads.

Timber floors are subject to rot, white ant attack and fire. Steel floors are prone to noise and rust. Concrete floors minimise or avoid all these issues.

- Individual pads are 800mm long

- No baulking noise

- Will not rust

- Treads every 200mm

- Less slip

- Stronger and last longer than timber

- Modules available for sale

- Compression tested – Elastic at 3 tonne, Fracture at 3.6 tonne

AUSTRALIAN PATENT: 2006100701

- Concretable drop in posts to prevent movement (standard on all ramps).

- Adjustable height front bumper.

- Sheeted sides.

- Closed in rails to prevent heads going through.

- Gate can block off more cattle coming up ramp if operator going into

the truck to pen up. - Gate can close off truck door to prevent cattle coming back whilst

operator penning up truck. - Rails behind truck block off gate prevent cattle going over side of ramp

if truck block off gate accidentally left in wrong position. - Concrete floor

- Walkway with handrail.

- High overhead bracing

* Concrete floor standard on all ramps! (except budget)

* Except adjustable height section

Ken & Libby Burkinshaw, Lockhart

“We needed two sets of yards. I did my homework very carefully before deciding on National Stockyard Systems. The rail spacing allows us to work sheep in the yards as well”